I'm currently working on simulating (in a very basic way) and designing a force controller for a linear drive.

There is a circular saw blade mounted on the linear drive cart. The linear drive will be set at a specific feedrate, given through a single between 1 and 10. (Unimportant atm for the question I think anyways...). Eventually the sawblade will come into contact with an object that will produce dampening feedforce of something around 40N that will jump +/- 10N...(learned through experiments). I would like to design the controller (PI, or LQI) with mathematica to reduce the feedrate in order to reduce the process forces, or rather control them to a specific referenced feedforce (25N for example)....Eventually a function of feedforce will be given and tracked during the entire cutting process. In this case, when reference force rises, the controller should increase the feedrate, and respectively drop it when the referenced force drops.

The feedforces can be directly measured with dynometer, and the feedrate adjusted programmatically. There is currently no position control for this system. Only feedrate can be given...hence the want to design this controller.

At the moment I'm completely unsure how to even model the collision of the sawblade with an object...Though for my purposes at the moment, I believe it's not required, as the saw motor dynamics are unimportant for the current form of simulation. I would like to model the linear movement of an object, that encounters a breaking/dampening/load force to approximate this collision/cutting process..If this is at all possible.

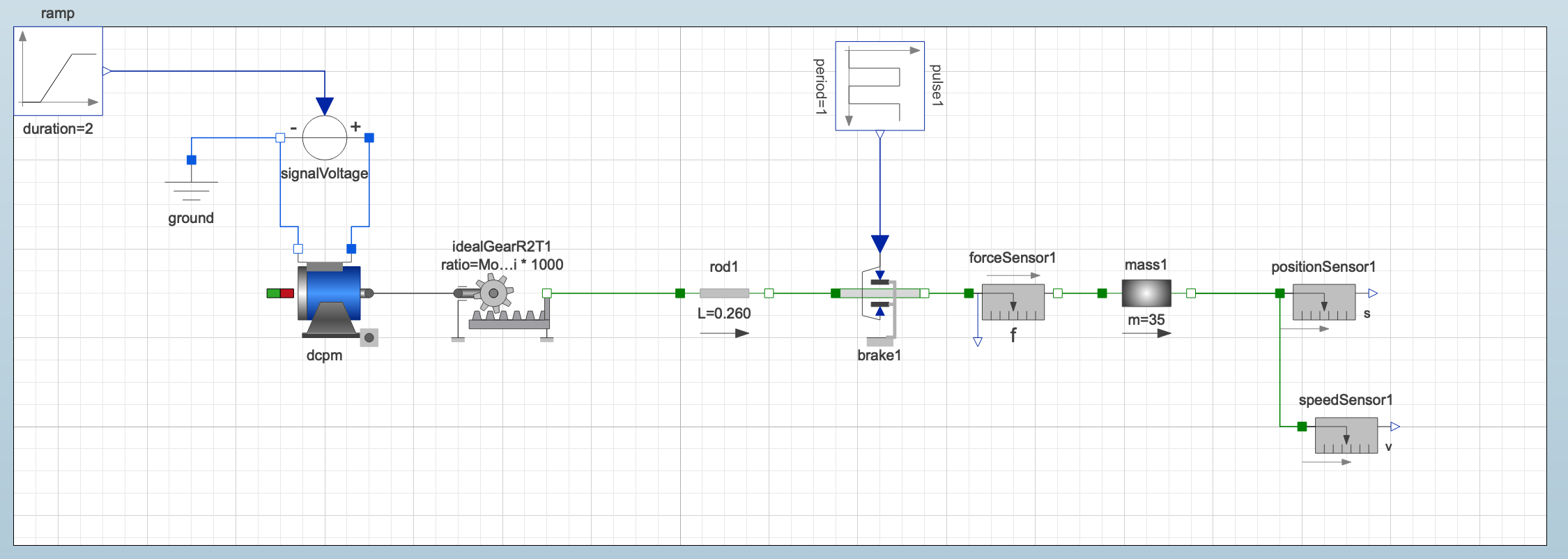

So far, as pictured, I have designed a simple rotational to linear rail, with a mass and force, plus position sensors.

This is agreeably very basic. However, if this load or dampening force or breaking force can be added to the system the way I imagine it.... I believe it will be accurate enough for my current purposes (Though I will gladly be taught how to do it better! :) )

My first thoughts were to add the breaking as pictured with a simple pulse signal...however I am unsure if this is ideal. How would one go about this?

Thanks for the help!

Attachments:

Attachments: